- Products

- For Heat Dissipation

- Thermal Interface Material

- Anti-bacterial Powder

- Mechanical Parts

- Optical Module

- Other Products

- Thermal Module

- Service

- Case

- Successful Case

- Simulation Case

- …

- Products

- For Heat Dissipation

- Thermal Interface Material

- Anti-bacterial Powder

- Mechanical Parts

- Optical Module

- Other Products

- Thermal Module

- Service

- Case

- Successful Case

- Simulation Case

- Products

- For Heat Dissipation

- Thermal Interface Material

- Anti-bacterial Powder

- Mechanical Parts

- Optical Module

- Other Products

- Thermal Module

- Service

- Case

- Successful Case

- Simulation Case

- …

- Products

- For Heat Dissipation

- Thermal Interface Material

- Anti-bacterial Powder

- Mechanical Parts

- Optical Module

- Other Products

- Thermal Module

- Service

- Case

- Successful Case

- Simulation Case

Nano-carbon Heat Sink Division

Nano-carbon Heat Sink Division: develops and produces nano-carbonheat sink on the basis of solid nano-carbon material

Nano-carbon material of Asink is 100% solid coating material.It's different from normal water-based coating and solvent-based coating because it takes air as dispersed medium to replacethe organic solvents which is harmful to environment.With our exclusive NSSCT(Nano Solid Surface Coating Technology),the homogeneous film can be formed on the surface of metal substrateand increases the radiation coefficient.We stick to the concept of being a green enterprise so that we only develop the technique of solid coating material,which is safer and recyclablecompared with liquid coating material.Compared with liquid coating material,solid coating material is safer and recyclable.Therefore,we can achieve the goal of being eco-friendly.

Features:

1、TIM can reduce the thermal contact resistance between the heat sink and the heat source to reduce the temperature.

2、The metal substrate can quickly transfer heat to the surface of the heat sink for the high thermal conductivity.

3、The nano-carbon layer on the surface can improve the cooling efficiency of the radiator.

Structure and Material:

The black part at the tpo is the solid nano-carbon layer (thickness: between 40-100 μm), whichcan improve the efficiency of heat dissipation. The silver part below is a metal substratelayer which can be processed to different shapes. The grey part is thermal interface material(TIM). TIM is optional and can be added depending on the structure of heat sink and customer’srequirements. The red part at the bottom is the heat source.

Thermal Module Division

Thermal Module Division: develops thermal module products to solve the problem of high thermal flux

Thermal module is generally used for system which has higher calorfic value or forced convection thermal system.Common components include heat pipe, heat conductive substrate,fin,fan or blower and vapor chamber.By function can be divided into two main parts:the heat sink and the convection system. The heat sink can enhance heat conduction and the surface area and reduce the ventilation resistance.The convection system is generally a fan, including axial fan and a blower.

Thermal module can be applied to laptop,server,industrial personal computer(IPC),game host,display card,projector and so on.

Product:

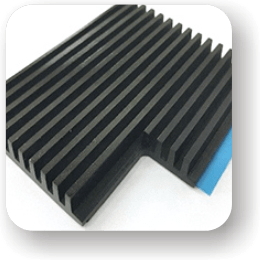

Aluminum-Extruded Thermal Module

Soldered HS Module

Soldered HS with Heat Pipe Module

Features:

Especially for chip or heating device with high thermal fluxFocus on the structure of product to achieve higher thermal performance

Structure & Material of Thermal Module:

Thermal module consists of heat sink and convenction system as picture shows.Thermal Interface Material(TIM,to reduce the thermal resistance) fills the vacancy between the heat sink and heat source. Therefore,the thermal energy transfers to heat sink(higher performance can be achieved if the heat sink is made of the material with high thermal conductivity). The fins on the heat sink can increase the cooling area,and the fan on heat sink can transfer thermal energy through forced convection.

Above is just one example.We will design the thermal module based on the product structure.Also we will take metal base(e.g. copper,aluminum and so on), heat transfer path(e.g. general metal heat sink,heat pipe,vapor chamber and so on),fin(to maximize the performance),fan(e.g. aixal fan,centrifugal fan and so on) and so on into consideration.

Thermal Interface Material Division

Thermal Interface Material Division: develops the thermal interface material to perfect the products for thermal solution

Thermal interface material is widely applied in electronic products to fill the vacancy between two materials to reduce the theraml resistance and enhance the thermal performance. Asink has complete supply chain of thermal interface and production line of thermal pad.Also we use professional inspection devices to ensure the quality of our products.

Features:

Reduce the thermal resistance between the heat source and heat sink to enhance the thermal performance.Also it can insulation and shock-absorbing effect to some degree.

Powder Coating Material Division

Powder Coating Material Division: develops powder coating material to provide our customers with eco-friendly functional solid powder coating material

Asink works hard to accumulate the experience,improve the technique and launch new products in these years.Therefore,we earn recognition in this industry and our customers. Our bread-winning product,powder coating material,has been applied in following industries:manufacuring,furniture,automobile,steel,processing and construction. Our products not only replace the expensive imported material but also open the market of the electronic information industry.We have won ISO9001 certification, passed UL test and received the order from an internationally known automobile brand."Creative,professional,eco-friendly and win-win" is Asink's core value and competiveness. Our powder coating material conforms the international environmental protection regulation,including ROHS and REACH.Our materials and products are both eco-friendly, and we have compete patent system and automated production.Also,we provide our customers with spray coating service by our advanced equipment.